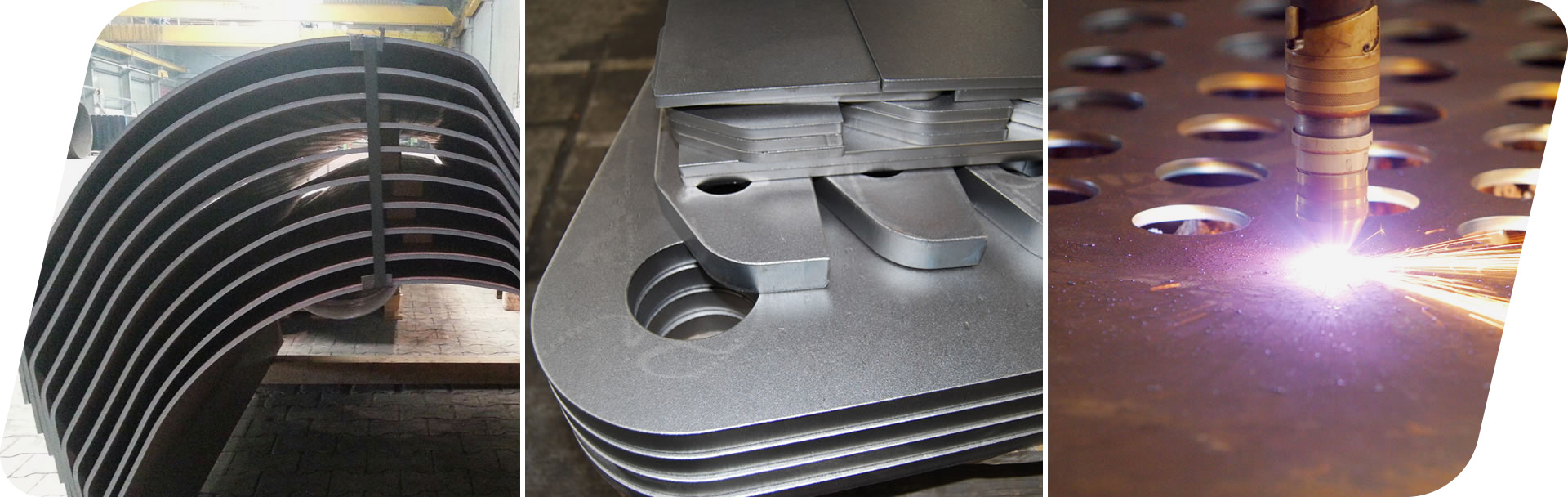

State-of-the-art systems technology, along with our personnel, who have acquired long-standing expertise, ensure that can we supply above-average quality with short and reliable delivery schedules. Depending on the quality, thickness, dimensions, tolerance and quality requirements, we manufacture up to 600 mm material thickness on our CNC-controlled oxy-fuel, plasma and laser cutting machines.

CNC-controlled plasma cutting machines

- Table size 5 x 28 m

- Material thickness 4 – 40 mm

- Cutting systems with up to 2 burners

- Programmable semi automated plasma bevel machine

- Signing for the preparation of welded structures or for forming

3D–CAD

The handling and production of three-dimensional components of all sorts is part of our daily work.

We can process all current file formats (for example .step, .iges, .prt, .ipt, .sldprt etc).

Flaming and laser tolerances

Flaming tolerances according to EN ISO 9013 or after consultation.

Preferred drawing formats

.dxf , .dwg

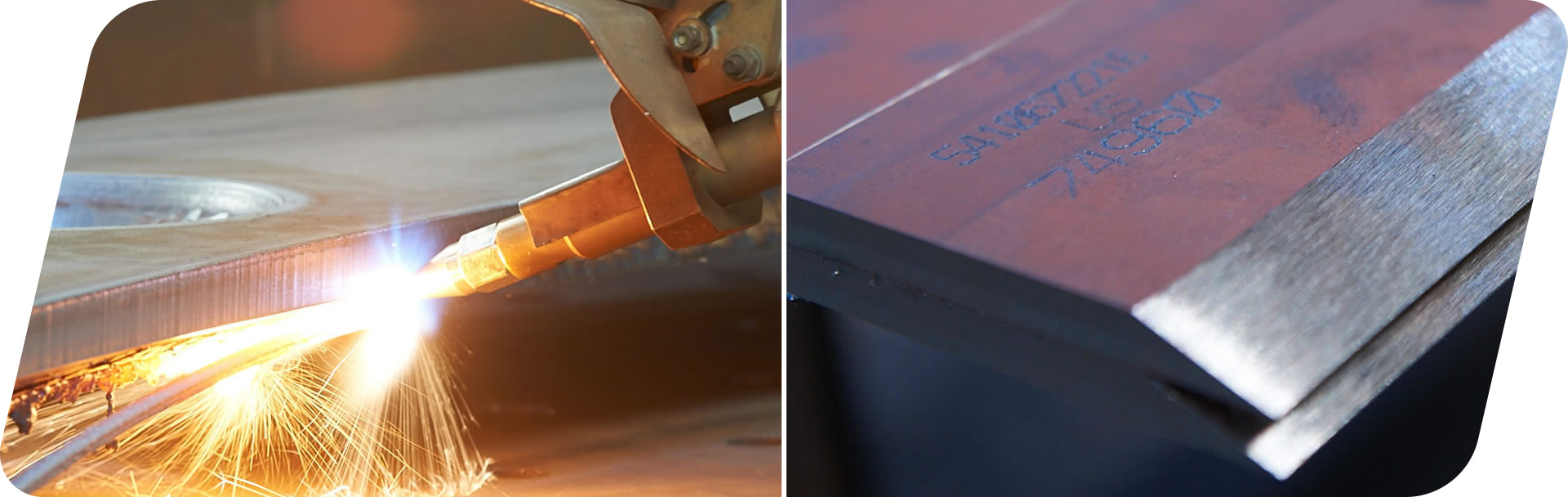

Weld seam preparation (bevelling)

In order to ensure an optimum seam connection during welding, it is necessary to prepare a chamfer on the burning blank.

We offer our customers different possibilities of production:

Mechanically introduced

- Grinding units:

– Bevelling at 9 m per cycle

– Workpiece thickness up to 100 mm and width from 100 mm

– Adjustment without need to rotate the component

– 85° upper and 45° lower chamfer - Beveller:

– no component length restriction

– Workpiece thickness up to 50 mm

Automatically introduced

- 6-axis robots (bevelling in two planes, as well as contours)

- Guaranteed repeat accuracy

- Bevel cut length up to 200 mm